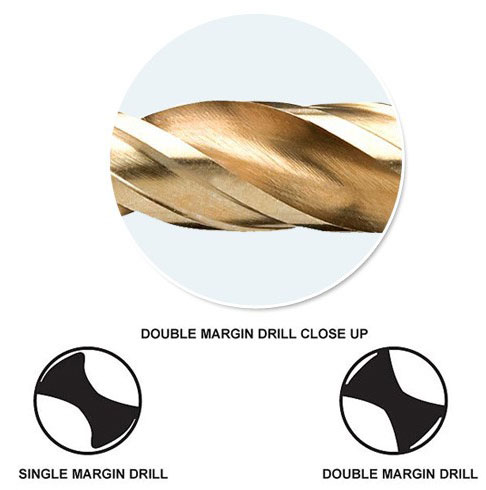

Double Margin drills have an additional margin ground behind the leading margin,

providing twice the number of contact points.

The second margin performs various functions to improve hole quality.

- The trailing margin burnishes the cavity, making a true hole and smoother finish, helping to provide a more concentric drilled hole

- A reamer finish can be achieved with double margin drills, eliminating a second operation.

- When a double margin drill is used with a drill bushing, the four margins locate in the bushing, providing increased bushing support in excess of 200%.

- When intermittent cutting is required, the double margin drill performs in two ways: Enhanced margin support in the first cavity cut, and support on breakthrough, which stops the drill from wandering when in contact with the work space.

- Drill back taper is more tightly controlled than a regular drill, enhancing a rounder hole location.

- 135-degree split point provides immediate self-centering on contact with the work piece, and reduces thrust, due to its notch-type web thinning at the chisel edge length. The split point is excellent for drilling harder materials (titanium, stainless steel, and high temperature alloys.)

- The bronze-gold drill color is an easy way to identify these tools as being cobalt aircraft drills, and is easy to group when resharpening.

- With all these features incorporated in this double margin drill, it is excellent for hand drilling.